4 Easy Facts About Bobcat Forks Shown

Resources:Â CNC machines could be the very ideal alternative for a job, but a job may be better suited by manual machines with a budget. The size of the machinery makes a difference whether the end product is oversized. A custom fabrication shop's tooling capability may be important influences on its capabilities and its metal products' quality.

Many firms who specialize in precision manufacturing use CAD/CAM software layout and to design the products to be fabricated. Achieve the specifications required to manufacture many products and CNC computers are programmed to do the particular tasks. CNC machines have gained popularity because of their ability decrease the cost of labor and to be exact.

Production type:Â The size of a production run short- or long term and low- or high-volume, ought to be among the considerations in selecting an customized fabrication service.

Front Loader Attachments Things To Know Before You Buy

Stock substances it is very important to make certain that a fabricator either has or can form the alloy which is going to be used to get a product. Should they have it's also worth looking into the suppliers reputation. A steel fabrication store that is specialized may work with exactly the steel provider for a lengthy time period. .

This guide gives a basic understanding of the various techniques metal fabrication, and considerations for choosing a fabricator. To learn more on related services consult with our product manuals or visit our Thomas Supplier Discovery Platform to find sources or view details on specific goods.

Welcome to Custom Metal Fabricators, Inc.. We've provided quality craftsmanship. From prototyping and initial conception to meeting and manufacturing, we offer the standard and professionalism you deserve.

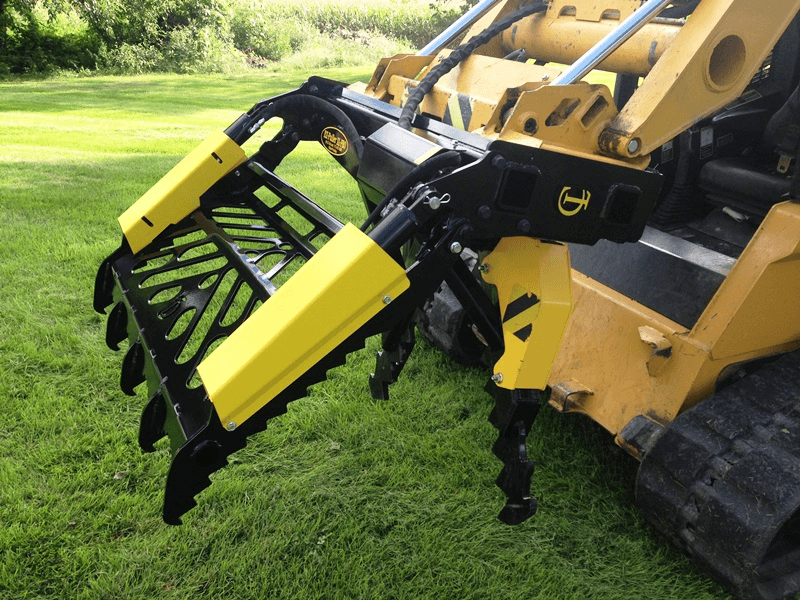

Not known Facts About Tree Puller For Skid Steer

Please review our fabrication capabilities , our services, and navigate a sample of the completed products. Whether you have a big project or even a small one, find out for yourself why our customers keep coming back.

At JP Metal Fabrication, we take great pride in our work and strive to meet and exceed client expectations on every project. With our extensive expertise, expertise, and gear, our manufacturing team is capable of taking on any project from the prototype stage. We work in many industries, both big and small.

We specialize in fast turn, precision sheetmetal and machining at competitive prices. We can manufacture individual custom-made parts or construct assemblies combining manufacturing, machining, welding, welding, plating, and final meeting. Precision and deliveries will be exactly what you may expect from JP Metal Fabrication. .

The Mahindra Accessories Ideas

An AISC, AWS, also WABO Quality-Certified Fabricator. average salary for metal fabrication A bondable and strong company devoted to decreasing your threat by supplying price. Clear communication with direct access to our top folks. And also an easygoing yet responsive team which can see you from begin to finish.

C L Fabrication

420 S 8th St, Clarinda, IA 51632, USA

(712) 542-5500

Things about Mahindra Accessories

In other words, welding joins together two parts of metal, glass, or thermoplastics with similar melting points and compositions utilizing mix. Fabrication is the evolutionary process of finishing and producing a metal product, from design and layout to formation. However its probable that many welders can manufacture, and its more likely that fabricators could weld. .

So, what are the similarities and differences between both Before your apprenticeship Program is filled out by you, Kaempf and Harris takes a look at the resources, processes, and safety precautions that enter every trade:

A collection including a pair of cleco fasteners along with numerous angle grinder discs, are available here. Metal fab applications cant be utilized for welding since that Procedure requires more special tools

Shrub Puller Fundamentals Explained

As for the similarities, the two professions require cleaning supplies to disinfecting the alloy. Pros use a wire brush and natural solvent, such as acetone or metal stair fabrication even a mild alkaline solution, or even a citrus-based degreaser with no butoxyethanol (a chemical compound that may lead to breathing and liver problems) to scrub away any grease, fatty deposits, along with germs. .

To clean the facility following a hard days work, fabricators and welders use sweepers and mops. For cleaning methods that are industry-specific, these transaction professionals often use flooring finishes, surface protection pictures and coatings, and electro-cleaners.

It goes hand-in-hand steel fabrication and welding with sheet steel manufacturing, Since welding is a metal forming procedure, and every transaction uses procedures that are similar, like bending and assembling, to receive the final item. To clarify, there are distinct approaches to weld, such as oxy acetylene, TIG (the most common type in fab shops), and gas metal arc (GMAW) welding. .